Custom Plastic Products Supplier & Manufacturer

We provide solutions to the challenges of advanced Polymeric Materials and Plastic Compounding of multicomponent composites. Our team is experienced in the relevant variables needed to reach your performance objectives. We have expertise in both the physical and chemical properties of plastics as well as providing solutions that lead to success in the end-use.

Extensive Knowledge

Using our extensive knowledge in material science and plastic processing, we deliver viable production and product development solutions for many end-market-applications.

Rapid Turnaround

Time is a valuable resource. With in-house equipment and skillsets, we are more nimble and able to deliver rapid results to help you get your product to market faster than other compounders.

Specialty Plastic Compounding Company

Plastic compounding starts with a base resin or polymer which has unique characteristics depending on the specific application. Utilizing additives, fillers, and reinforcers, a wide range of properties can be achieved. Including improved conductivity, flame retardancy, wear resistance and structural strength. Physical attributes such as color and feel can be customized to your specific needs.

OUR SERVICES

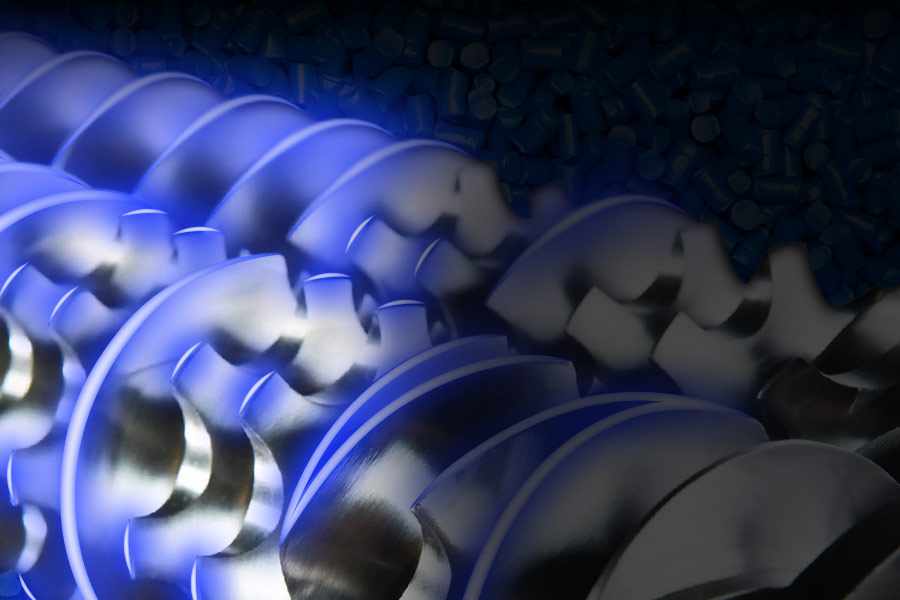

Product Development

Our efficient approach to new product formulation uses novel process design with internal twin-screw extrusion pilot assets for optimum product development. Our plastic experts are able to conduct small development batch trials and quickly screen product and processing parameters for proof-of-concept demonstration and small-scale manufacturing.

Specialty Compounding

By incorporating a wide range of additives, we can create and/or add functionality to base resins including conductivity, aesthetics, flame retardance, toughness, strength, thermal stability, and surface properties.

Masterbatch Concentrates

We have strong expertise in masterbatch concentrates, a concentrated compound of colors and/or performance additives that economically adds functionality during processing. We have extensive knowledge on a wide range of polymer resins and blends, additives, modifiers, fillers, and nanocomposites.

Fully Formulated Compounds

We specialize in a ready-to-use, fully formulated compound for downstream processing in the production of injection molded parts, fibers, films, and FDM filament for additive manufacturing. Such compounds can be as simple as a base resin with an additive (nylon with a reinforcing fiber filler) or one with several resins and additives (an automotive interior polypropylene (PP) TPO formulation).

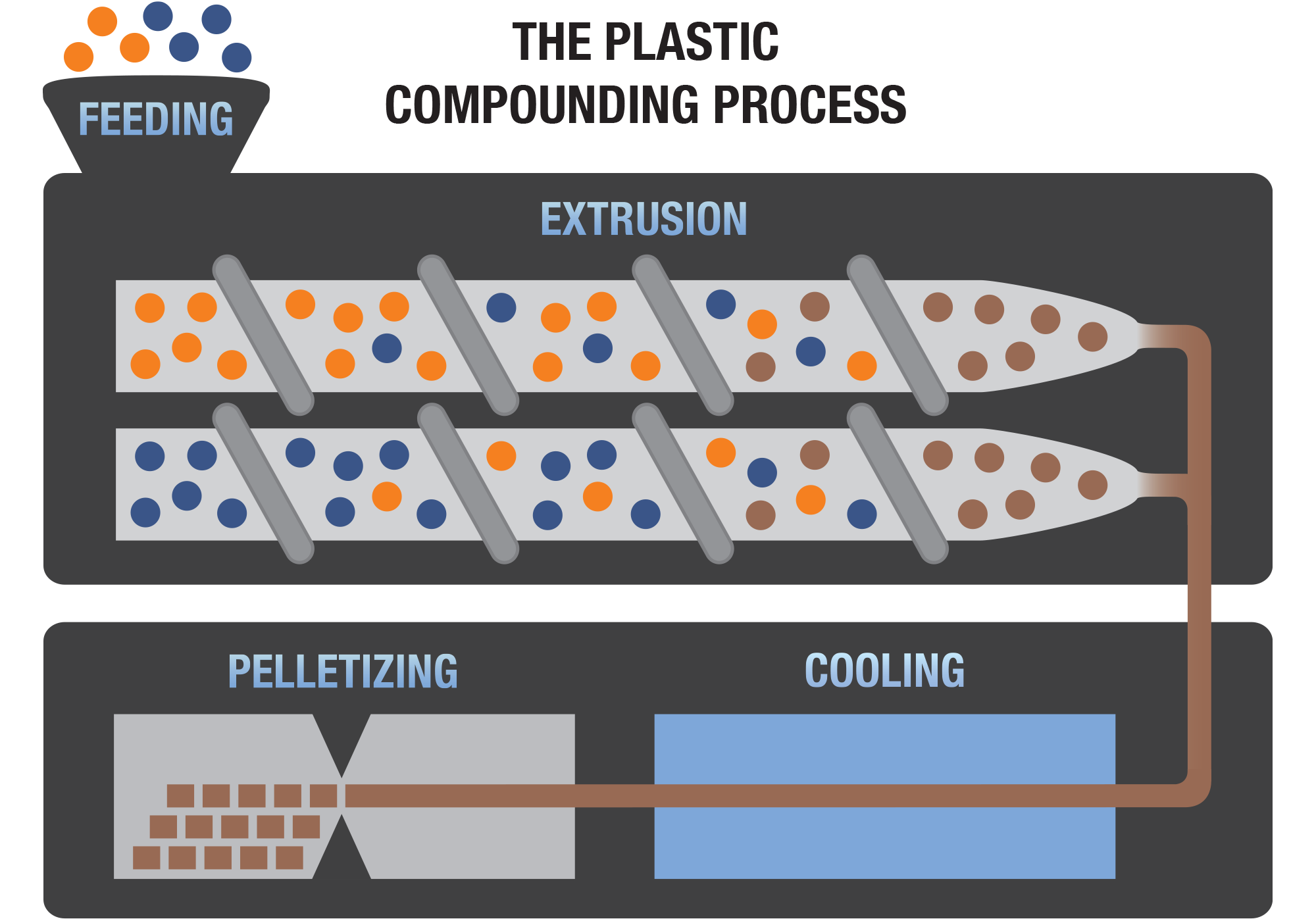

The Plastic Compounding Process

The Compounding process involves blending and melting of plastics with other ingredients and additives. The goal is to acheive desired attributes in the physical, electrical or thermal characteristics of the plastic. This process results in a composite or compound with a specific material behavior.

Solutions for Custom

& Specialty Polymers

Custom Polymer Compounding

Tailored to Your Requirements

Small Scale Laboratory Plastic Compounding

We are a small to medium scale plastic compounding operation focused on scaling new compounds and processes. Our size allows us to be nimble enough to focus on the specific performance objectives and requirements of our clients. Combining our experience in both the physical and chemical properties of plastics with thermoplastic composite technologies we are able to partner with our clients to improve their products.

Learn How Our Custom Plastic Compounds Can Help Your Business.